Product Category

Related Products

Oil Well Liquid Level Analyzer

Product Category :

- Details

-

- Commodity name: Oil Well Liquid Level Analyzer

Product Overview

During an oil well's production process, the liquid level's depth in the annular space of the oil casing is referred to as the dynamic liquid level. The purpose of dynamic liquid level testing is to determine the height of the liquid analyzer in the oil well. In the exploration and development of oil fields, continuous real-time monitoring of dynamic liquid level data helps analyze relevant formation parameters, which provides guidance for the next steps in oil well production. SLIC’s oil well liquid analyzer tester provides reliable measurements for various liquid level parameters in oil field production.

Working Principle

The oil well liquid level analyzer uses the principle of infrasound combined with filtering technology and low-frequency automatic recognition algorithms to locate the liquid level wave and collar wave positions automatically, thereby deriving the liquid level depth. By instantaneously releasing a small amount of casing gas, an expansion shock wave is generated in the gas at the wellhead’s annulus. The infrasonic component of the sound wave propagates downward along the annulus and encounters the reflected sound waves generated by collars, sound markers, and gas-liquid interfaces. These reflected sound waves act on a micro acoustic transducer, which converts them into electrical signals. After amplification, filtering, and A/D conversion, the electrical signals are converted into recognizable liquid-level curves through digital processing.

Product Classification

The product can be categorized into fixed and portable types. The portable version can be equipped with a nitrogen cylinder or an infrasonic wave generator as the sound source, according to the customer's on-site needs.

Key Features and Competitive Edges

- Automatic liquid-level depth testing at variable intervals.

- The limit alarm function can be set according to requirements.

- Local handheld operation and automatic release of casing pressure are available.

- Remote modification of test parameters for the on-site tester is available.

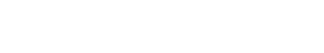

- Data can be viewed anytime, anywhere via mobile phone, tablet, or PC.

Key Technical Features

- Built-in 8-segment variable interval continuous monitoring function that can be further modified for other applications.

- Unique channel filtering technology effectively deals with valve blockage and leakage problems.

- Multiple remote data transmission solutions are available to meet various application scenarios for automation and informatization.

- Optional handheld control devices can be equipped to enable real-time local monitoring of equipment operation.

- Advanced single-piece valve connection technology is used to meet high-pressure monitoring requirements.

- Proprietary filtering technology and low-frequency automatic recognition algorithms are used to calculate liquid level depth.

Technical Specifications

- Testing Depth, m: 0 to 3500.

- Testing Accuracy: ±10m/1000m.

- Testing Interval, min: 2 to 6000.

- Equipment Pressure Resistance, MPa:0 to 10.

- Number of Intervals: 8 segments.

- Main Material: 2Cr13.

- Equipment Power Supply: DC24V.

- Tubing Thread: 2 7/8''.

Process Flow Diagram

Product Images

Pressure type

Self-adaptive

Related Products